Welcome to PRECAST-AA-CO₂

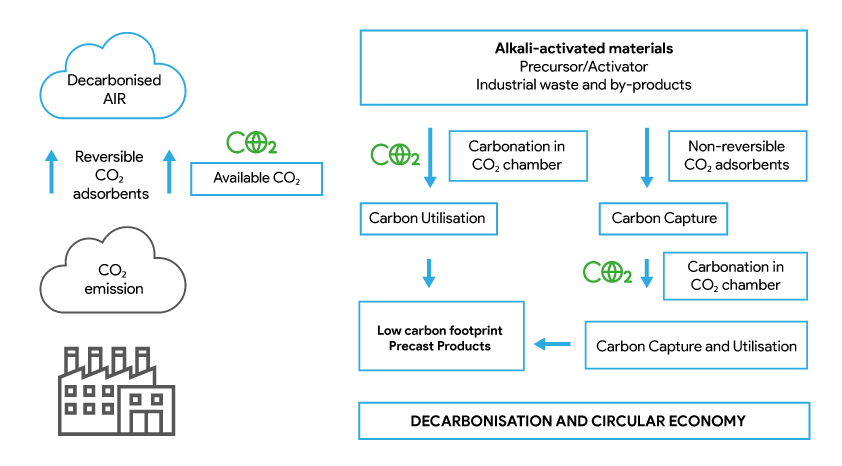

PRECAST_AA_CO2 aims to contribute to climate change mitigation (decarbonisation) and the transition towards a circular economy in the construction sector, in line with the emission reduction targets set out in the European Energy and Climate Policy Framework 2021–2030. In doing so, it seeks to foster a competitive, low-carbon, green economy by 2050.

PRECAST_AA_CO2 is part of the Green Transition axis of the Recovery, Transformation and Resilience Plan, presented by the Government of Spain on 30 April 2021 and approved by the European Commission on 16 June 2021. Among the environmental goals of the green transition are climate change mitigation and adaptation, as well as the shift towards a circular economy (Regulation (EU) 2020/852 of the European Parliament and of the Council of 18 June 2020).

PRECAST_AA_CO2 has brought together a strong multidisciplinary and interdisciplinary research and working team, fostering powerful synergies between FQM-391 “Materials and Applications” and TEP-227 “Construction Engineering”. At the international level, the team also includes a leading researcher: Dr J. de Brito from IST (University of Lisbon, Portugal).

The Project

SUMMARY

The PRECAST_AA_CO2 project develops innovative strategies for the manufacture of precast concrete elements using alkaline activation and with low or zero CO2 emissions. Five main approaches are used:

- Obtaining precast concrete by alkaline activation using industrial waste of suitable chemical composition (circular economy + significant reduction of CO2 emission).

- Addition of CO2 adsorbents developed in the framework of the R+D+i Project “PRECAST-CO2” to the alkaline-activated concretes.

- Curing of alkaline-activated precast concrete in CO2 atmosphere (CO2 as a product of commercial interest and CO2 capture).

- Incorporation of recycled aggregates (RA) from construction and demolition waste (CDW) (circular economy) with higher carbonation capacity.

- incorporation of biomass fly ash as activator and additions of CaO that will also act as CO2 adsorbent and help reduce the curing temperature (energy savings).

RESEARCHERS

Dr. Enrique Fernández Ledesma

Dr. David Suescum Morales

CALL, REFERENCE AND FUNDING

- Call: Strategic Projects for the Ecological and Digital Transitions, within the 2021–2023 State Plan for Scientific, Technical and Innovation Research. (2021)

- Reference: TED2021-132095B-I00

- Duration: 01/01/2023 – 30/09/2025

- Funding: MCIN/AEI/10.13039/501100011033 and the “NextGenerationEU” / PRTR: Recovery, Transformation, and Resilience Plan—Funded by the European Union—NextGenerationEU]

OBJECTIVES

The General Objective of PRECAST_AA_CO2 is the mitigation of climate change, adaptation to climate change and the transition to a circular economy, through the manufacture of precast concrete elements, based on new alkaline-activated cement-based materials with low or zero CO2 emissions. The aim is to meet the emission reduction targets approved in the European Energy and Climate Change Policy Framework 2021-2030, and to achieve a low-carbon and competitive economy by 2050.

- To obtain precast concrete elements by alkaline activation of industrial wastes of suitable chemical composition.

- To study the CO2 adsorption of alkaline activated precast concrete elements under different pressure and temperature conditions.

- To determine the maximum percentage of addition of CO2 adsorbents developed in the framework of the R+D+i Project “PRECAST-CO2” to alkaline-activated concretes.

- To determine the most favourable percentage of incorporation of biomass fly ash as activator and addition of CaO that act as CO2 sinks in alkaline-activated concretes

- To determine the maximum percentage of substitution of natural aggregate by recycled concrete aggregate and mixed, coarse and fine fraction, in the alkaline-activated concretes.

- Selection of the most suitable alkaline-activated concrete mixes for industrial-scale manufacturing of prefabricated elements.

- Transfer to the productive sector and society by promoting industrial guidelines for the manufacture of sustainable building materials.

ARTICLES

Our findings will be published in high-impact scientific journals, showcasing the development of CO₂ capture technologies for sustainable construction.

CONFERENCES

The PRECAST-AA-CO₂ team actively participates in national and international conferences to present research progress and foster collaboration with experts worldwide.

THESES

This project has generated several PhD research opportunities, contributing to innovation in low-carbon materials.

DISSEMINATION

- Media publications on CO₂ capture in construction.

- Workshops and lectures for students and industry professionals.

- Participation in public engagement events to raise awareness about sustainable construction practices.

News

ORGANIZED BY

FUNDED BY

DECARBONISATION OF PRECAST CONCRETE WITH NEW ALKALINE ACTIVATION AND CO2 CURING TECHNOLOGIES (PRECAST_AA_CO2)

COLLABORATING ENTITIES / ORGANIZATIONS